|

Princeton University |

|

|

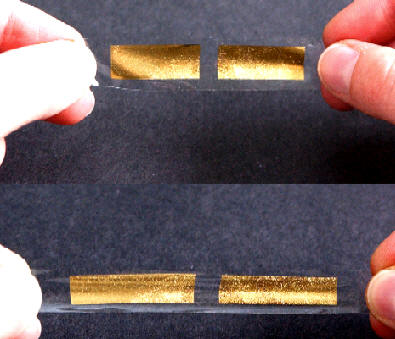

Nanocrystalline Si TFT Stretchable conductor Macroelectronics makes use of integrated circuits bigger than semiconductor wafers. Flat panel displays and medical X-ray sensors are current macroelectronic products. Sensor skin and e-textiles will serve as human/machine interfaces, and mechatronic materials will marry structural to electronic functions. Advanced macroelectronic technology is based on transistor backplanes made on flexible, shapeable, and elastic substrates. Macroelectronics are made by thin film techniques. The transistor backplane provides power, switching, computation and communication. The functional front plane is built on top of the backplane. The function may be a liquid crystal, a luminescent or light sensing device, a touch sensor or an actuator element. Encapsulation caps the structure and protects it. Because the functional layers may be only micrometers thick, the weight of macroelectronic systems is as light as their substrate and encapsulation will allow. Such thin active electronics also pose fascinating scientific challenges. We were first to introduce silicon transistors on flexible foils of glass (1995) and steel (1997), and have a long record of developing transistor technology on organic polymer substrates. All of these are entering industrial use. We have been helping companies start their transistor-on-plastic programs. Our novel combinations of silicon thin film electronics with foils of plastic, metal or glass also are beginning to find application outside of macroelectronics, for example, in tunable high-precision optical filters, very-low pressure sensors, and microfluidic chips. Updated on 28 January 2004. |

||