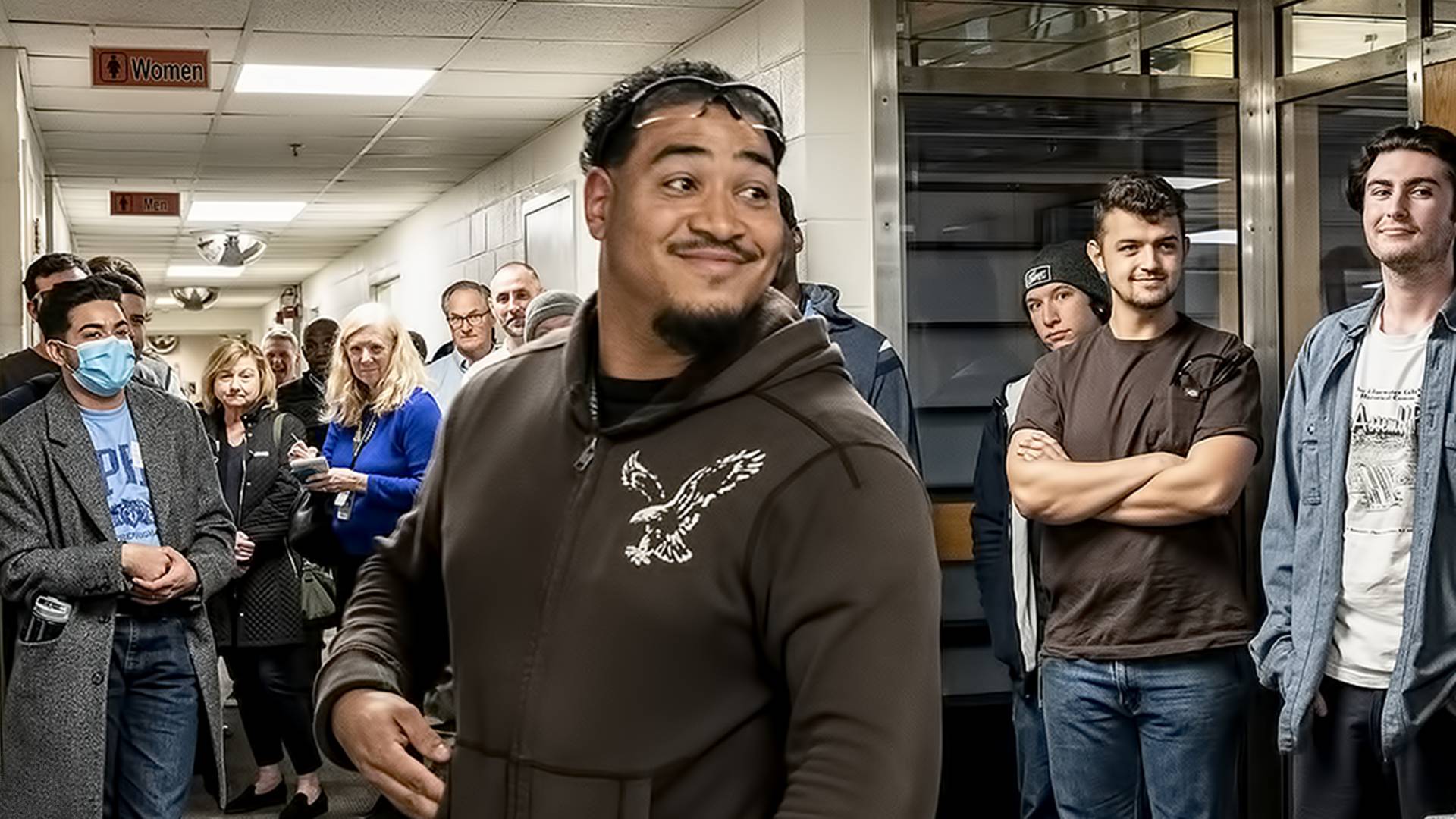

Steve Armstrong, an HVAC apprentice, center, and other apprentices outside the Computer Center.

Steve Armstrong served in the U.S. Army for three-and-a-half years as an electrician. When he was discharged, he trained to work in heating, ventilation and air conditioning. That’s when he learned about the Princeton Plasma Physics Laboratory’s four-year apprentice program, in which apprentices receive on-the-job training and classes in cutting-edge technical fields.

“I would say I was lucky. I stumbled upon this apprenticeship, and it worked out for the best,” Armstrong said. “The people I work with are very knowledgeable. They have a lot of real-world knowledge. Whatever question I have, I can get an answer.”

Armstrong is one of 14 apprentices enrolled in PPPL’s four-year apprenticeship program, a nationally recognized program that now serves as a model for other programs. PPPL, which is based at Princeton University and funded by the U.S. Department of Energy, was recently named an apprenticeship ambassador by the U.S. Department of Labor (DOL) as part of President Joe Biden’s Apprentice Ambassadorship Program aimed at providing training for high-paying jobs in a range of industries.

PPPL’s program is the first registered apprenticeship program in the United States focused on fusion energy and engineering and is partially funded by a $27,000 grant from the Growing Apprenticeship in Nontraditional Sectors (GAINS) program from the U.S. DOL and the New Jersey Department of Labor.

It was started in 2018 by Steve Cowley, PPPL director, based on a similar program at Culham Centre for Fusion Energy in the United Kingdom and has grown from four to 14 people, expanding from traditional trades like electrical and mechanical engineering, welding, and HVAC to include fields like information technology (IT), cybersecurity and environment, safety and health (ES&H). The apprentices complete 8,000 hours of paid on-the-job training and 576 hours of technical instruction.

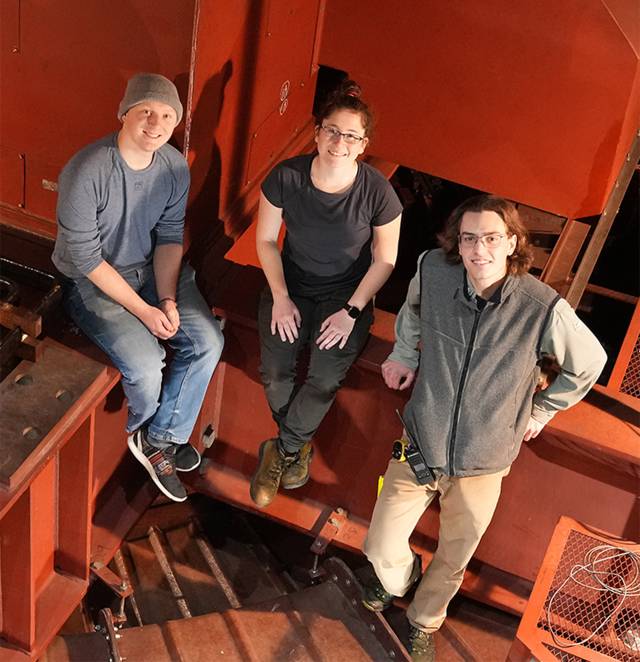

Apprentices in the flywheel of one of the motor generators that help power the National Spherical Torus Experiment-Upgrade, PPPL’s flagship experiment: From left: Aaron Floyd, Abby Fellnor, and Sheehan Twomey.

“Our apprentices are an enormous benefit to the lab, the state of New Jersey, and the nation,” Cowley said. “They are committed to our mission of developing fusion, a source of clean, safe, and abundant energy, and they bring such vitality to the lab. I’m so glad to see them here.”

Andrew Zwicker, head of strategic relationships, said the apprentice program is looking for early-career technicians from a variety of backgrounds. “The success of our laboratory depends on us finding the best people we can and that means finding a diverse group of people,” he said.

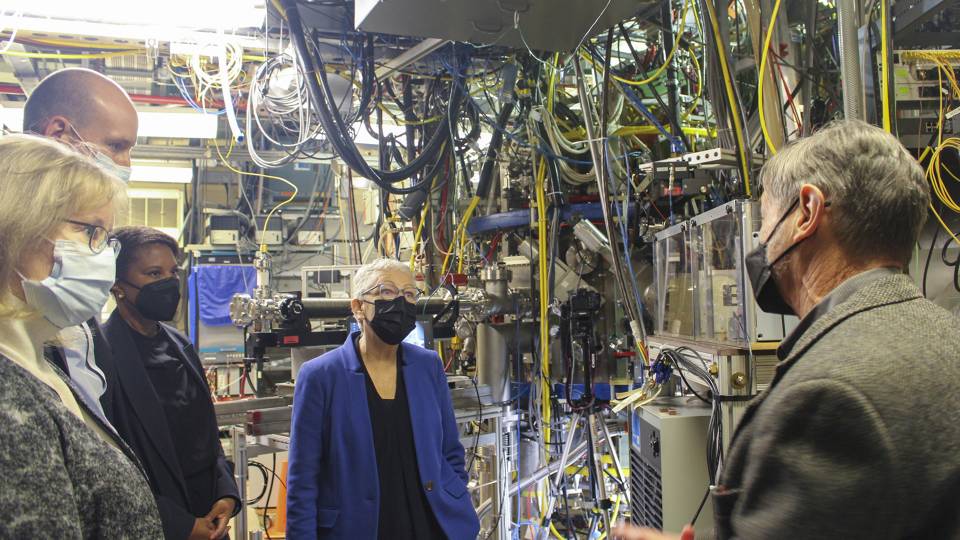

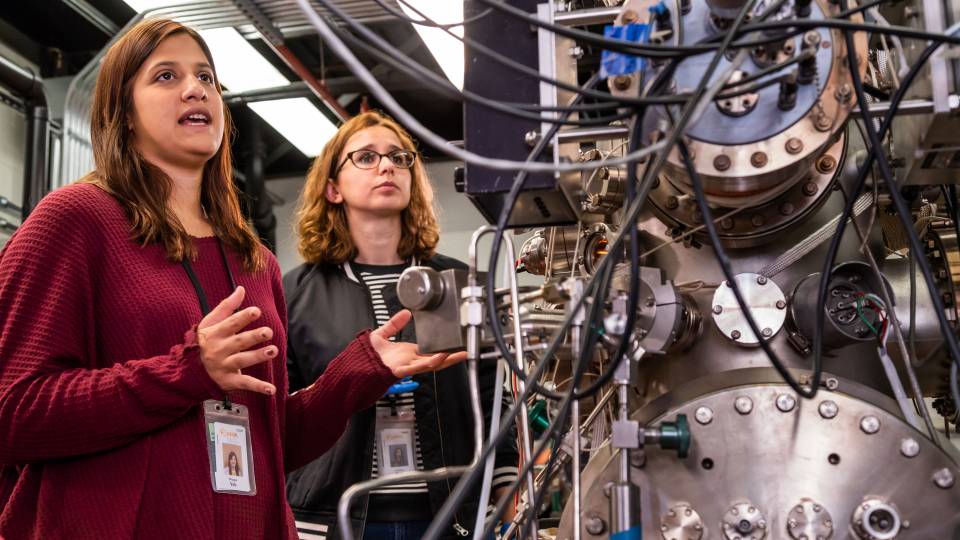

PPPL invited people considering an apprenticeship, as well as state and national officials, and educators to the laboratory during several in-person and hybrid events in honor of National Apprentice Week last month. They learned about the program and saw the apprentices at work, including welding coils for the Facility for Laboratory Reconnection Experiment, a next-generation collaborative facility that will explore magnetic reconnection, the process responsible for solar flares and other astrophysical phenomena. Apprentices also demonstrated their work on complex electrical systems for PPPL’s flagship experiment, the National Spherical Torus Experiment-Upgrade (NSTX-U).

Sean Hough, an electronic apprentice, showed visitors the Remote Glow Discharge Experiment in the Science Education Laboratory, in which users can manipulate a plasma from anywhere in the world. Hough is helping to upgrade, the experiment as one of three projects he’s working on, along with the system for a personnel safety system for the NSTX-U. “My work has taken me all over the lab,” he said.

Dennis Alvarado, one of two information technology apprentices, said he and apprentice Zachary Simpson have learned a great deal about information technology by being assigned to help people throughout the laboratory with their IT issues on the IT Help Desk. “PPPL really wants to lay a strong IT foundation to begin with before advancing more advanced concepts,” he said.

Stephan Dupnak, a second-year welding apprentice, welding.

Sheehan Twomey, a fourth-year electrical apprentice, went to vocational school after high school and worked as an electrical technician. “I was skeptical of getting a college degree that I wasn’t going to use; I wanted to get my hands dirty,” he said. Now, after finishing all his technical classes at Mercer County Technical School, he is taking classes at Mercer County College. He said he’d like to join the permanent staff when he finishes his apprenticeship this year. “I would love to stay. I definitely want to join the lab full-time afterwards,” he said. “This place has a lot to offer.”

Diana Adel, the apprenticeship program administrator, noted that the initiative will not only train a highly skilled and motivated workforce of the future but also allow for a transfer of knowledge from PPPL’s seasoned professionals.

Among the guests on the tour were Nicholas Toth, director of the New Jersey Office of Apprenticeship, and Jim Harris, project manager of the Workforce Development-Industry Partnership Unit. “I’m just soaking it all in,” Harris said. “This model seems like it’s on the cutting edge.”

Also attending was Michael Blatt, state director for the U.S. Department of Labor Office of Apprenticeships. “You’re taking traditional apprenticeships and you’re raising it to this incredibly complex level,” Blatt told PPPL apprentices and PPPL leaders.

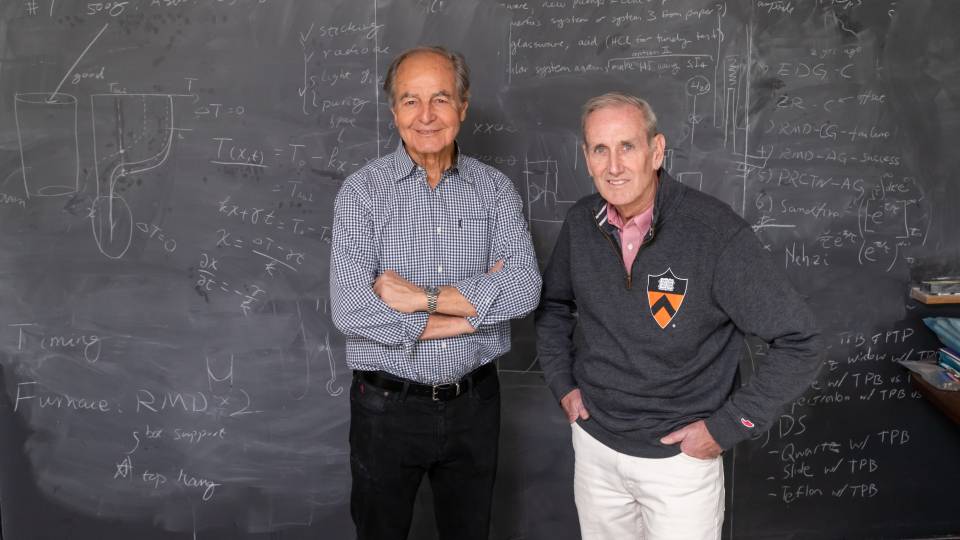

During the tour for National Apprentice Week, Twomey showed visitors one of two 700-ton steel flywheels on massive motor generators that are used to power the NSTX-U when it is operating. “It’s a very special place to work,” Twomey told visitors. “You’re really never going to work on something like this anywhere else.”

Abby Fellnor, a first-year apprentice who works with Twomey, had been “a little unsure of what I wanted to do with my life before I started this apprenticeship,” she said. “I came to the realization that I like to work with my hands. I like to work hard, but I also like to think. This is an excellent opportunity for people who want to work and learn at the same time.”

Mike Kozic, a motor generator engineer who is one of Twomey and Fellnor’s mentors, said the experienced technicians have enjoyed teaching the early-career apprentices. “Each of them brings their own characteristics and skills to the group, and they all work together. It’s one of the best parts of the job here. They’re the next generation.”

More information about PPPL’s apprenticeship program is available on the PPPL website.