Bottle 3

Conditions

Bottle 3

Conditions

Bottle 3 Simulation Results

Bottle 3 Simulation Results

Simultation Results -

Figures

Simultation Results -

Figures

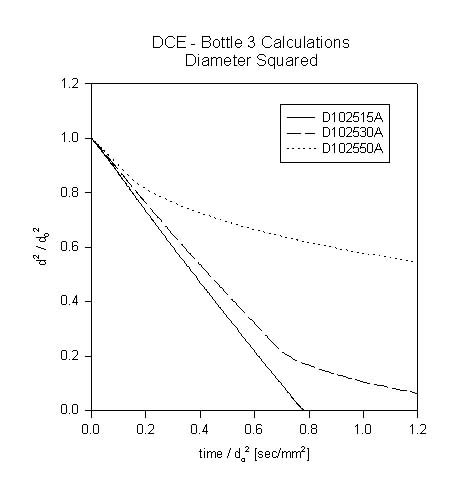

The following is a plot of diameter-squared vs. normalized time for Bottle 3 test cases D102515A, D102530A, and D102550A.

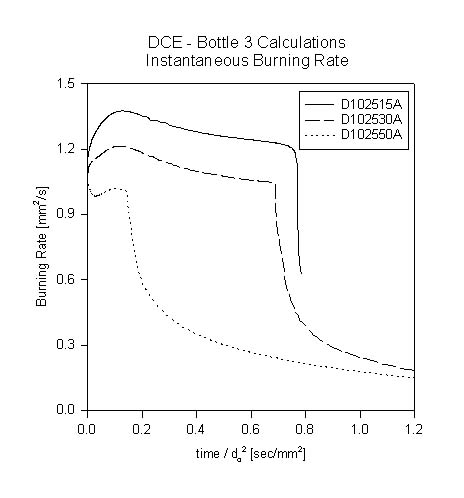

The following is a plot of instantaneous burning rate vs. normalized time for Bottle 3 test cases D102515A, D102530A, and D102550A.

http://www.princeton.edu/~fldryer/nasa.dir/current3.htm

Last updated: June 11, 1997