|

|

||||||||

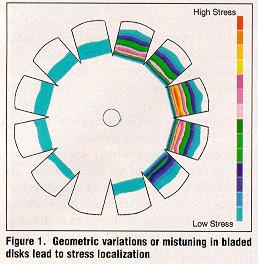

| High

frequency blade vibrations in a gas turbine can cause blade failure and

engine destruction. The top diagram shows a numerical calculation on a

blade-disc assembly in which the stress amplitude is very high in several

blades due to resonance coupling. The stress amplitude is seen to be highest

at the blade roots.

The bottom photograph shows a single blade subjected to a vibration test at the blades natural frequency. This blade is from the fourth stage of the compressor spool in an F100-220 engine. The relatively high amplitude of the blade tip is indicated by the 'blur' region of the photograph. Surface modification methods such as laser shock peaning help to improve fatigue performance. From: AFRL Technology Horizons, December 2001 |

||||||||

|

||||||||

|

||||||||