Structural Health Monitoring of US202/NJ23 Bridge at Wayne, NJ |

|||

|

|||

US202/NJ23 BRIDGE AT WAYNE, NJ |

|||

The US202-NJ23 is a highway overpass close to Wayne, New Jersey, constructed in 1983-1984 close to Wayne, NJ. Structurally and functionally, it is a typical example of an overpass frequently found across the USA. It consists of two bridges (north and south bound) and each bridge contains several simply supported spans. Each span is built of several steel girders that support a concrete deck. The girders are built-up sections with varying flange thickness. The bridge is skewed, thus the girders have different lengths. Varying cross sections and varying girder lengths, along with several perpendicular stiffening trusses (diaphragms) create a structurally complex overpass. View to bridge from below is given in Figure 1, and detail of a support is given in Figure 2. Extensive testing of the US202/NJ23 overpass has been performed by several international teams in the frame of the International Bridge Study (IBS), which is a part of the Long-term Bridge Performance (LTBP) Program put forth by the Federal Highway Administration (FHWA). The research presented in this paper is a part of this program. |

|||

Figure 1: US202/NJ23 Bridge, view from below.

|

Figure 2: Detail of a support. |

||

SHM OF US202/NJ23 - MOTIVATION AND AIMS |

|||

SHM is the most frequently applied to signature structures, i.e. those with major economic, symbolic, or aesthetic significance, while it is relatively scarcely applied to ordinary, typical structures found all across the USA. A single typical structure can be judged as less important than any signature structures, the totality of typical structures represents a large majority of national bridge infrastructure and their preservation is as critical as the preservation of signature structures. Thus, SHM can truly be declared as universally useful only if its benefits are proven on typical structures too. The overall aim of this project is to research affordable SHM solutions that are applicable to typical structures. The US202/NJ23 overpass is a good example of a typical structure and it provides an excellent opportunity to explore the usefulness and to assess the benefits of SHM applied on typical structures. SHM lab teamed up with Roctest/SMARTEC SA in order to deploy an affordable and durable monitoring system that provides with reliable information about the bridge performance and health condition. In the event that some insufficiencies of the SHM system or sensor network are identified, they will be reported and improvements will be proposed. |

|||

SHM OF US202/NJ23 - EXPECTED OUTCOMES |

|||

Scientific contributions. Monitoring results will increase knowledge basis concerning the real structural behavior of typical bridge structures and will help to build reliable algorithms for damage and performance degradation detection based on objective data. More specifically, dynamic strain due to traffic load (heavy tracks and free vibrations) is periodically measured without interrupting the traffic on the bridge, and the results are analyzed based on statistical methods and structural models. At the cross-section level, the quality of interaction between the steel girder and concrete slab is being analyzed. At the girder level, the natural frequencies and mode shapes of the two girders are being determined and their dependence on temperature is being analyzed. At the bridge level, the responses of the two monitored girders are being correlated and the global bridge performance is being assessed. Educational contributions. The SHM of US202/NJ23 Bridge is being integrated in the graduate course CEE 539 on SHM. Students were involved in all phases of project including design of monitoring strategy, installation of the system, data handling, interpretation and analysis. An undergraduate student is developing his senior thesis within the project in 2011/2012, and the others will follow. Broader impact. A successful development of the method will lead to more systematic instrumentation and more optimized preservation of similar bridges at national and international scale. The SHM will provide an increased level of safety for the bridge users, and an improved management for the bridge owner is expected. The Bridge is a part of IBS and LTBP program, and thus it has a high profile among the researchers, companies, and authorities (DOTs), which can greatly help disseminate results of the project. Beside the course on SHM, the instrumented bridge will be of great support to the Short Course on SHM using FOS. |

|||

DEPLOYMENT OF MONITORING SYSTEM |

|||

Two girders on the second south-bound span were instrumented with discrete Fiber Bragg-Grating (FBG) long gage sensing technology, at the quarter points and mid-span, in total at six locations. Fiber-optic sensing (FOS) technologies are used since the optical fibers feature high sensitivity, durability and long-term stability. The FBG long-gage sensors can monitor average strain, average curvature, and temperature, and allows global structural monitoring in both static and dynamic mode. Deformed shape, modal parameters, and the concrete-steel interaction are evaluated from the measurements. The sensors were surface mounted using L-brackets that were glued to the girder flanges. The installation was performed by SHMlab graduate students Dorotea Hoeg Sigurdardottir and Yao Yao under the supervision of Prof. Glisic. Photographs taken during the installation are shown in Figures 3-9. |

|||

Fig. 3: To bridge.

Fig. 6: Verification of position of L-brackets. |

|||

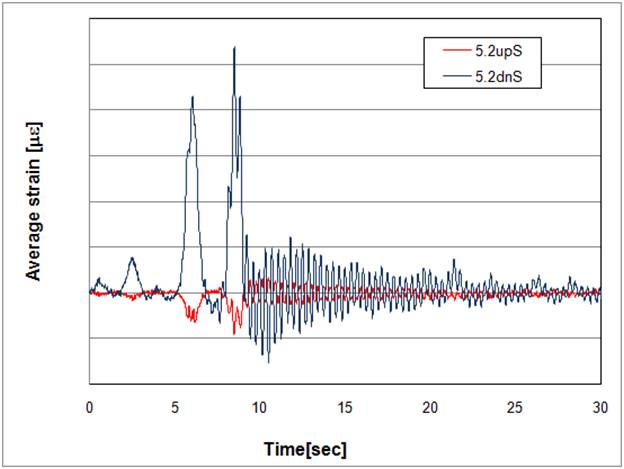

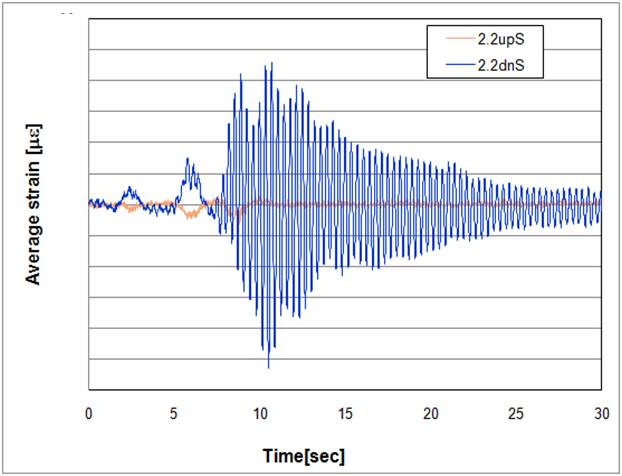

Dynamic average strain generated by traffic was recorded and several events registered. Future analysis will include calculations of average curvature, position of the center of gravity of the composite cross section, natural frequency, thermal expansion, and correlation in behavior of the two girders. Figures 10-11 show dynamic strain measurements at mid-spans of two monitored girder. |

|||

Figure 10: Strain measurements at at mid-span of girder nr. 5. |

|

Figure 11: Strain measurements at at mid-span of girder nr. 2. |

|

ACKNOWLEDGEMENTS |

|||

This project has been realized with important support, great help, and kind collaboration of several professionals and companies: SMARTEC SA, Switzerland Drexel University, in particular Professor Emin Aktan, Professor Frank Moon, and graduate student Jeff Weidner New Jersey Department of Transportation Long-Term Bridge Performance (LTBP) Program of Federal Highway Administration PB Americas, Inc., Lawrenceville, NJ, in particular Mr. Michael S. Morales, LTBP Site Coordinator Rutgers University, in particular Professors Ali Maher and Nenad Gucunski All IBS partners Kevin operated the lifts |

|||

|

|||