Research: Autonomic Self-Healing Materials Using Electric-Field Induced Colloidal Aggregation

David L. Milius

Advisors: Dudley A. Saville and Ilhan A. Aksay

When high stress is applied to structural materials, catastrophic failure of the material occurs shortly after the initial defect forms due to stress concentration. It is highly desirable to develop a novel material which can autonomic heal initial defects to prevent or postpone material failure. Currently there are only a very limited amount of materials which exhibit these self-healing characteristics. Two examples are SiC [1] and MoSi2 heating elements, which form a protective silica coating on their surface after being scratched. However, this process occurs only at extremely high temperatures and is thus not suitable in many applications. Recently, a microcapsule method [2] has been proved to self heal polymer composites at ambient conditions by releasing microencapsulated healing agent upon crack intrusion. By manipulating thermally reversible Diels-Alder reactions, a transparent polymer material with self-repairing functionality at ~120°C is developed [3].

To expand the self-healing concept to other technically important materials, such as metals and ceramics, new methods involving electric-field induced colloidal aggregation are being explored. This technology is being tested initially with a system that contains two concentric cylinders (the inner one has a thin layer of insulating ceramic coating), with an electrical field applied to the system as shown in the following schematic. Between the two cylinders is a colloidal dispersion of polystyrene or silica particles, which are used to repair defects that occur in the inner cylinder when high stress is applied. When a defect occurs in the insulating coating, underneath metal is exposed to create high current density at the damaged site, causing colloidal particles to coagulate around the defect [4].

A schematic for a self-healing system that uses the electrohydrodynamic coagulation of particles to close a defect in a cylinder wall.

The defect is not completely repaired because the voids between the colloids prevent the formation of a completely dense surface. To fill in these interstitial spaces, simultaneous metal electrodeposition within the void spaces by dissolving and electroplating of the anodic metal electrode (sacrificial anode) ultimately fills the void [3]. This process produces a coating of a ceramic/metal composite at the site of the initial defect.

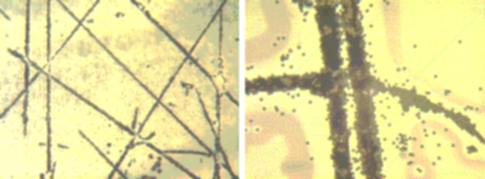

Optical microscope images of colloidal particles (2µm polystyrene) forming on an ITO coating on a PET substrate. (Left) Cracks in ITO layer formed by bending the substrate induces the preferential coagulation of particles in the cracks. (RIght) A higher magnification image shows the formation of close-packed particles in the cracks.

References

1. S. Govindarajan, B. Mishra, D. L. Olson, J. J. Moore, J. Disam, "Synthesis of Molybdenum Disilicide on Molybdenum Substrates," Surf. Coat. Tech. 76-77, 7-13 (1995).

2. S. R. White, N. R. Sottos, P. H. Geubelle, J. S. Moore, Mr. R. Kessler, S. R. Sriram, E. N. Brown, S. Viswanathan, "Autonomic Healing of Polymer Composites," Nature 409, 794-797 (2001).

3. X. Chen, M. A. Dam, K. Ono, A. Mal, H. Shen, S. R. Nutt, K. Sheran, F. Wudl, "A Thermally Re-mendable Cross-Linked Polymeric Material," Science 295, 1698-1702 (2002).

4. M. Trau, D. A. Saville, and I. A. Aksay, "Assembly of Colloidal Crystals at Electrode Interfaces," Langmuir 13 [24] 6375-81 (1997).

5. P. Sakar, X. Huang, O. Prakash, and P. Nicholson, "Electrophoretic Deposition to Synthesize Advanced Ceramic/Ceramic Laminar Composites," in Advances in Ceramic-Matrix Composites N. P. Bansal, ed. (American Ceramic Society:Westerville, Ohio, 1993) p. 39.

For more information, please contact Dave Milius. See the Ceramic Materials Laboratory web page for more information about our group and its research.

![]()

![]()

![]() ©

Princeton University, Department of Chemical and Biological Engineering

©

Princeton University, Department of Chemical and Biological Engineering

Ceramic Materials Laboratory. All Rights Reserved.