Research: Optically-Tunable Colloidal Crystallization

William D. Ristenpart

Advisors: Dudley A. Saville and Ilhan A. Aksay

We are investigating the physics underlying a recently developed and novel method for producing two-dimensional colloidal crystals. [1] This technique employs UV light to guide the assembly of two-dimensional colloidal crystals on the surface of an electrode.

Experimental apparatus (not to scale).

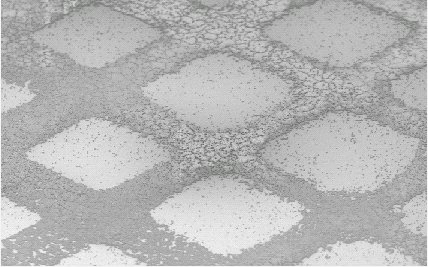

The experimental apparatus is depicted in the figure above. An aqueous colloidal dispersion is placed between two parallel electrodes made of indium tin oxide (ITO), which is an optically transparent semiconductor. [2] The top electrode is illuminated in specified regions by shining UV light through a mask. When an external voltage is applied, the colloidal particles deposit on the surface of the top electrode and then begin to aggregate in the illuminated regions. A representative pattern that results from this process is shown in the figure below. This aggregation process has been shown to occur with a wide range of colloidal types (both metallic and polymeric) and sizes (from 10 nanometers to 100 microns). [3-5]

Scanning electron microscope images of a pattern composed of 2Ám polystyrene particles. The dark (particle-filled) areas correspond to regions illuminated by UV, while the white (relatively empty) areas correspond to regions where the mask blocked the UV light. [1]

This technology could be of use in any application that requires a specified surface be coated with a particular type of colloid. For example, miniaturized bioreactors or 'lab-on-a-chip' devices could make use of this technology. [6] Photonic band gap materials could also be fabricated with this technique. [7]

However, the underlying physics of the process are not understood. Current theory focuses on fluid flow induced by the electric field, but the extant theories contain ambiguities and fail to predict observed phenomena. [8-10] Therefore, the primary objective of this research is to determine the underlying mechanism of optically-tuned colloidal crystallization.

To accomplish this, fundamental questions regarding the nature of the fluid flow in the system must be answered. Therefore, I am investigating the fluid mechanics in the system depicted above. One method of tracing fluid movement in the cell is particle tracking velocimetry. Currently, we are making in situ observations of the aggregation process and using custom- designed image analysis software to analyze the particle velocities. A typical time sequence of the aggregation process is shown in the animated picture below.

Time sequence of UV-induced aggregation process. Particles are 2 Ám polystyrene spheres. Circular light region in center of image is the region illuminated by UV light; the diameter is 300 Ám. Each frame represents 2 minutes of real time.

References

![]() 1.

R. C. Hayward, D. A. Saville, and I. A. Aksay, "Colloidal Crystals with

Tunable Micropatterns: Current Density Modulation with UV-light During

Electrophoretic Deposition," Nature 404 [6773] 56-9

(2000).

1.

R. C. Hayward, D. A. Saville, and I. A. Aksay, "Colloidal Crystals with

Tunable Micropatterns: Current Density Modulation with UV-light During

Electrophoretic Deposition," Nature 404 [6773] 56-9

(2000).

2. J. van den Meerakker, E.A. Meulenkap, M. Scholten, J. App. Physics 74 (1993).

3. M. Trau, D. A. Saville, and I. A. Aksay, "Field Induced Layering of Colloidal Crystals," Science 272 [5262] 706-09 (1996).

4. M. Giersig, P.J. Mulvaney, J. Phys. Chem. 97 (1993).

5. A.T. Poortinga, R. Bos, H.J. Busscher, Biotechnology & Bioengineering 67 (2000).

6. O.D. Velev, E.W. Kaler, Langmuir 15 (1999).

7. Y.N. Xia, B. Gates, Y.D. Yin, Y. Lu, Adv. Mater. 12 (2000).

![]() 8.

M. Trau, D.A. Saville, I.A. Aksay, "Assembly of Colloidal Crystals at

Electrode Interfaces," Langmuir 13 [24] 6375-81

(1997).

8.

M. Trau, D.A. Saville, I.A. Aksay, "Assembly of Colloidal Crystals at

Electrode Interfaces," Langmuir 13 [24] 6375-81

(1997).

9. Y. Solomentsev, M. Bohmer, M. Anderson, Langmuir 13 (1997).

10. Y. Solomentsev, S.A. Guelcher, M. Bevan, J.L. Anderson, Langmuir 16 (2000).

For more information on this research topic, please contact Bill Ristenpart. Additional information concerning the CML can be found on our website.

![]()

![]()

![]() © 2001 Princeton University, Ceramic Materials Laboratory.All Rights Reserved.

© 2001 Princeton University, Ceramic Materials Laboratory.All Rights Reserved.