Researchers at Princeton and Google are using a ventilator designed and built at Princeton in an effort to automate and improve controls for all types of ventilators.

Spurred by the demands of the COVID-19 pandemic, researchers at Princeton and Google are applying mechanical engineering and artificial intelligence to increase the availability and effectiveness of ventilation treatments worldwide.

Ventilators and their support equipment are expensive and complex devices that require expert attention from doctors and other highly trained medical workers. The devices must be carefully calibrated and monitored to ensure they are meeting a range of parameters — pressure, volume, breath rate — tuned to each individual patient. Often, these measures change during treatment, requiring further tuning.

If that monitoring and adjustment is handled by artificial intelligence, it could ease the burden on medical workers and allow ventilators to be deployed in areas with staffing shortages. That was the logic that led Elad Hazan, a professor of computer science and director of Google AI Princeton, and Daniel Cohen, an assistant professor of mechanical and aerospace engineering, to launch the project.

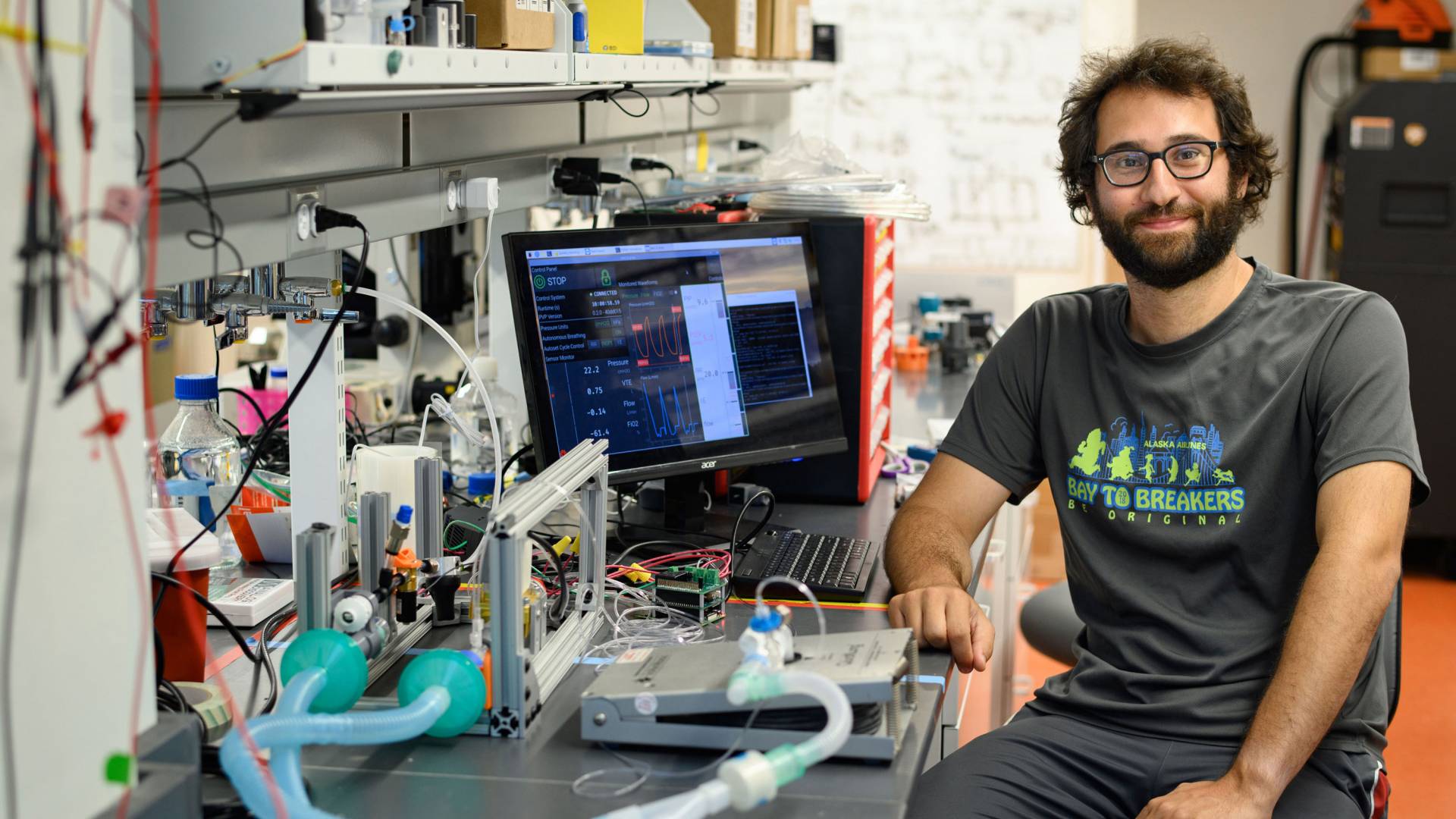

Graduate student Daniel Suo and senior Paula Gradu are part of a team of researchers using AI to improve the way ventilators assist patients.

“Modern ventilators seek to maximize clinical outcomes while at the same time protecting patients from excessive levels of pressure and volume,” said Daniel Notterman, a board certified pediatric intensive care physician with experience managing patients with respiratory failure, who is also a lecturer with the rank of professor in molecular biology. “Although conceptually simple, the regulation of ventilator performance is extremely complex. This effort provided the opportunity for experts in programming, engineering and clinical medicine to rethink many of the usual solutions, under the leadership of Professor Cohen.”

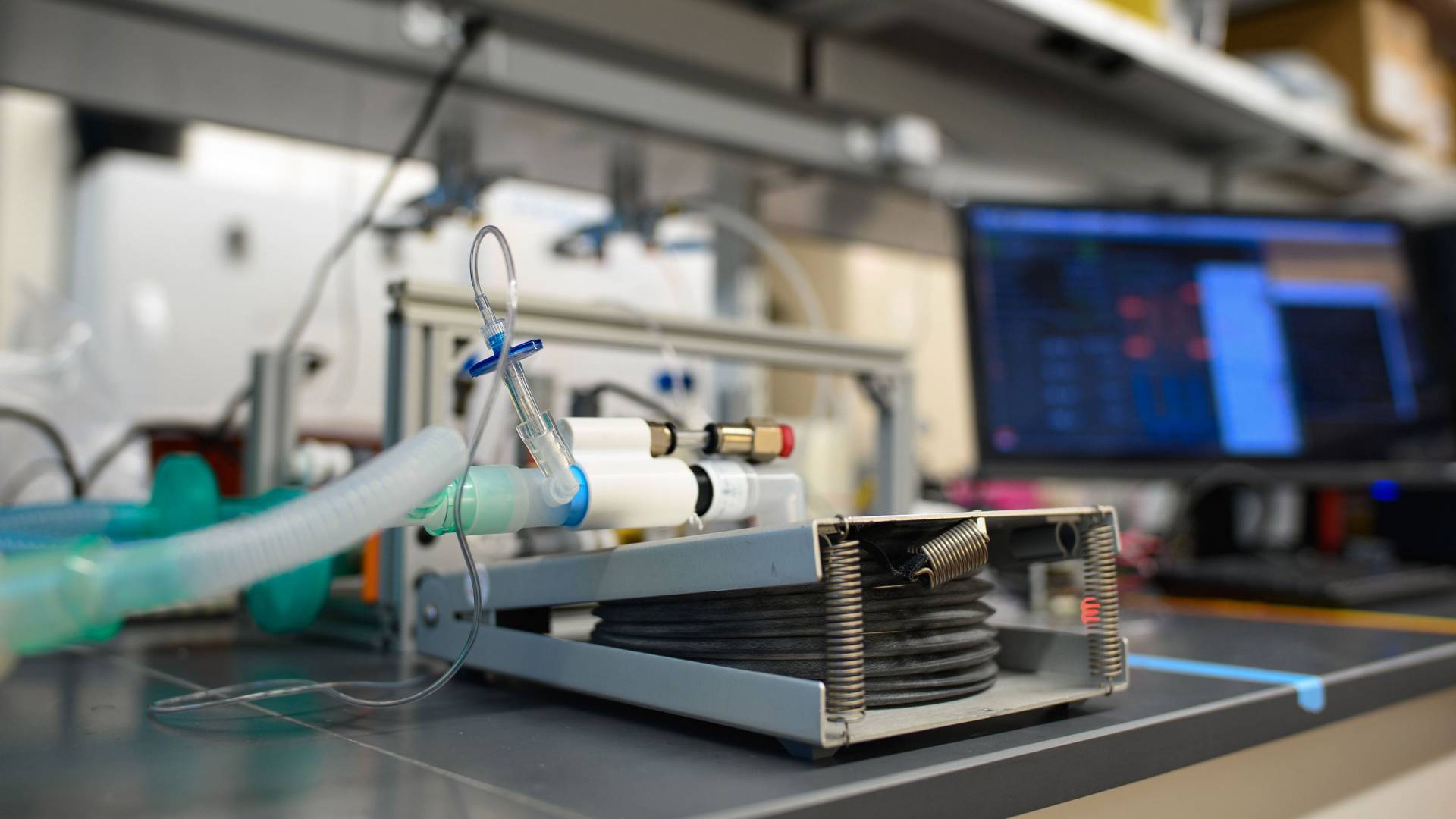

Since the initial COVID-19 outbreak last spring, Cohen’s team had been working to design low-cost ventilators using readily available parts. Initially, Cohen met with Hazan to discuss a control system for the new design. But the researchers realized that artificial intelligence could improve controls for all ventilators, not just the type designed at Princeton.

“The hypothesis is that applying AI tools can … make systems more robust and safer,” Hazan said.

Access to Cohen’s ventilator has been critical, Hazan said. The physics underlying breathing is complex, and breaking the fluid dynamics down into working equations is generally impractical and inaccurate. So instead of approaching the control problem through the physics of the lungs, the researchers ran experiments on the Cohen team’s ventilators and applied machine learning to uncover patterns in the data that would guide the safe and effective operation of the ventilator.

Tom Zajdel, a post doctoral researcher, was part of the team that designed and built a new ventilator at Princeton. The open-source design uses readily available parts.

Designing a low-cost ventilator that “goes together like Legos”

The development of the ventilator began as part of an effort by Cohen and Notterman to design a new system that was inexpensive and could be assembled from off-the-shelf parts.

“It basically goes together like Legos,” said Julienne LaChance, a graduate student in Cohen’s lab who led the prototype construction efforts from her garage. “I picture my high school robotics team putting this together.”

The ventilator is now fully built and meets key FDA performance standards, while costing less than $1,500 — a tenth or twentieth the price of commercial ventilators, Cohen said. The team is now actively seeking manufacturing partners to help push for regulatory approval, especially in less affluent countries in need of ventilators.

“We have been using robust, simple parts that we put together with a lot of very well done software and coding,” said Cohen. “We are trying to develop a generalized platform that anyone can work with, or improve upon, anywhere in the world, even after the pandemic.”

Researchers from Hazan’s lab include senior Paula Gradu; graduate students Xinyi Chen, Udaya Ghai, Edgar Minasyan, Karan Singh and Daniel Suo; and recent Ph.D. graduates Naman Agarwal and Cyril Zhang. In addition to LaChance, Notterman and Cohen, the local Princeton ventilator team includes postdoctoral researchers Tom Zajdel and Manuel Schottdorf, senior research software engineer Grant Wallace, and graduate students Sophie Dvali and Zhenyu Song, as well as a number of external collaborators.

Editor’s note: For the full version of this story, visit the Engineering website.